Tire News & Information

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

The process of manufacturing a tire is a complex and fascinating journey that combines science, engineering, and craftsmanship. From the selection of raw materials to the final inspection, each step plays an important role in creating a product that ensures our safety and comfort on the road.

Tire manufacturing involves a series of carefully orchestrated stages, each requiring precision and expertise. The process begins with the compounding and mixing of various raw materials, followed by the preparation of tire components, the intricate tire building process, vulcanization, and rigorous quality control measures.

In this article, we will delve into the world of tire manufacturing, exploring the key stages and technologies involved in creating these essential components of our vehicles. We will also discuss the materials used, the importance of quality control, and the environmental considerations surrounding tire production and recycling.

What is the tire manufacturing process?

The tire manufacturing process is a multi-step journey that transforms raw materials into the finished product we rely on for our daily transportation. It involves a series of stages, each critical to ensuring the quality, performance, and safety of the tire.

The key stages of tire manufacturing include:

- Compounding and mixing: The process begins with the careful selection and blending of raw materials, such as natural and synthetic rubbers, carbon black, silica, and various additives. These ingredients are mixed together in large internal mixers under precise conditions to create a homogeneous rubber compound.

- Component preparation: The rubber compound is then processed into various tire components. This includes extruding or calendering the rubber into sheets or strips for the inner liner, sidewalls, and treads. Textile reinforcements, such as polyester and nylon, are coated with rubber and cut to size for use in the body plies and belts. Steel wire is also coated and wound into hoops to form the tire beads.

- Tire building: The various components are assembled on a tire building machine in a specific order. The inner liner is laid down first, followed by the body plies, beads, sidewalls, and belts. The tread and any additional protective layers are then applied to complete the "green tire"—an uncured tire ready for vulcanization.

- Vulcanization and curing: The green tire is placed into a mold and inflated to press the components together and give the tire its final shape. The mold is heated to a high temperature, causing the rubber compound to vulcanize and form a strong, elastic material. The curing process can take anywhere from 10 to 30 minutes, depending on the size and type of tire.

- Final inspection and quality control: After vulcanization, tires undergo a thorough visual inspection for any defects or irregularities. They are also tested for uniformity, balance, and other performance characteristics using specialized equipment. Tires that pass all quality checks are then labeled, packaged, and shipped to distributors or customers, such as SimpleTire.

Tire manufacturing is a complex process that combines various materials, components, and technologies to create a high-performance product. Each stage is carefully monitored and controlled to ensure the highest quality standards are met, resulting in tires that provide reliable performance, comfort, and safety for millions of vehicles worldwide.

Raw materials used in tire manufacturing

The core of tire production involves a sophisticated mix of diverse rubber types. These materials are meticulously chosen for their ability to meet specific performance criteria. Synthetic options like styrene-butadiene and polybutadiene, crafted from petroleum-based chemicals, form the backbone of the tire's structure, known for their resilience and capability to endure various road conditions.

To enhance the tire's robustness and efficiency, reinforcing agents are employed. Silica and carbon black significantly contribute to the tire's overall strength and performance. Silica is particularly valued for improving grip and reducing fuel consumption, while carbon black aids in reinforcing the tire's structure, ensuring it can withstand extensive use without compromising safety.

Beyond the primary rubber compounds, a range of supplementary materials are incorporated to refine the tire's features. Chemical additives such as vulcanizing agents and accelerators are essential for solidifying the rubber during the curing process. Protective agents, including antioxidants and antiozonants, guard against environmental damage. Structural integrity is bolstered by incorporating textiles like rayon and aramid fibers, complemented by steel wire, which fortifies the tire's framework, ensuring it holds its shape and supports the vehicle effectively.

Compounding and mixing

The transformation of raw ingredients into a tire begins with meticulous formulation, where various materials are combined following exact recipes tailored for each tire part. This stage demands precise measurements and a deep understanding of the properties each material brings to the mix. The result is a well-balanced blend that sets the stage for the tire's overall performance and durability.

During the subsequent mixing phase, powerful industrial machines known as Banbury mixers facilitate the integration of these ingredients. These machines operate with precision, using intense heat and carefully applied pressure to ensure a uniform blend. The mixing process is critical, as it determines the consistency and quality of the rubber compound, which must remain pliable for molding and shaping in later stages.

Once the blending achieves the desired uniformity, the compound exits as continuous sheets or strips, poised for further processing. These forms serve as the groundwork for the tire's structural components, ready to be shaped into specific parts like treads and sidewalls, essential for the tire's final construction.

Tire Component Preparation

The creation of tire components involves transforming raw rubber into vital parts. This process starts with shaping the rubber into specific forms for various sections of the tire. Using advanced machinery, rubber is molded into profiles for the inner liner, sidewalls, and treads. This molding ensures each part meets the tire's design specifications, providing essential functions like airtightness and road grip.

For structural integrity, textiles play an important role. Materials such as polyester and nylon are integrated into the tire through a precise coating process with rubber. This ensures a strong bond, allowing the textiles to enhance flexibility and provide support. These coated reinforcements are then cut to precise dimensions, ready to serve as body plies and belts that strengthen the tire's framework.

An essential part of the tire's structure is the bead, which secures it to the wheel. Steel wires, treated for corrosion resistance, are shaped into hoops. This process ensures the tire remains firmly attached to the rim, preventing air leakage and maintaining stability. The careful preparation of each component is vital for the tire's overall performance and safety on the road.

Tire building process

During the tire-building stage, precision is essential as all components unite to form the initial structure of a tire. This task is performed on a tire-building machine, a specialized apparatus that assembles materials in a designated order. It starts with the installation of the inner liner, serving as the foundation that ensures the tire remains airtight, crucial for maintaining consistent air pressure.

Subsequently, the machine adds layers of body plies. These plies, fortified with textile elements, provide necessary support and resilience. The beads then follow, positioned meticulously to ensure they fit snugly against the wheel rim, securing the tire in place and preventing air escape.

The assembly then proceeds with the integration of the sidewalls, designed to endure environmental elements while maintaining the tire's shape. Steel belts are applied next, enhancing the tire's toughness and its capacity to resist external impacts and maintain structural integrity. The final stage in this process involves attaching the tread, which is crafted for optimal road contact and performance. Tread patterns are tailored to the tire's specific application, ensuring maximum traction and handling. This intricate layering concludes with the addition of any extra protective elements, preparing the tire for the curing phase, where all parts will be permanently bonded into a unified, efficient tire.

Vulcanization and Curing

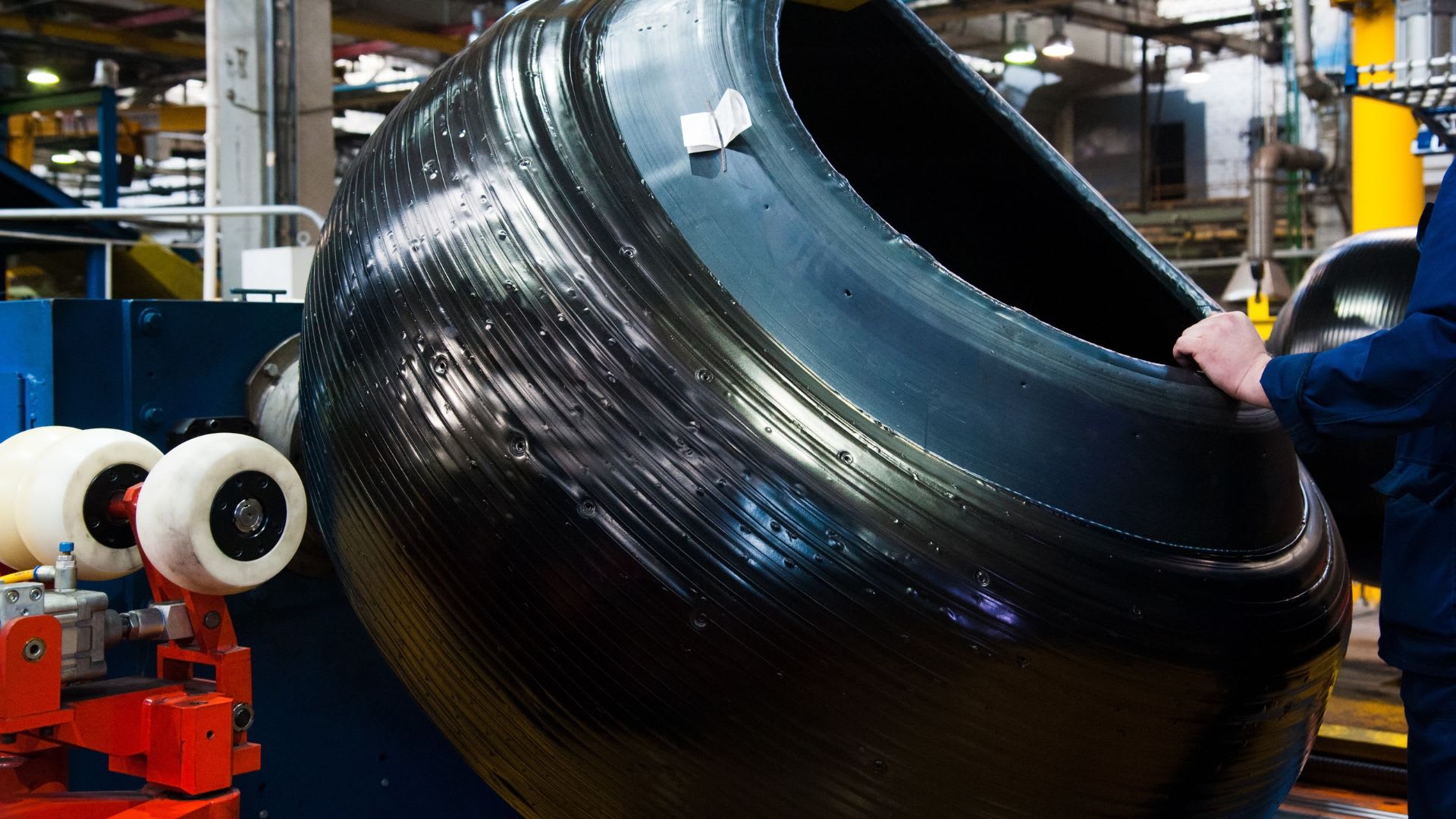

After assembly, the tire proceeds to the vulcanization stage, where it undergoes its final transformation. This involves placing the tire into a specifically designed mold that imprints the tread pattern and any necessary sidewall details. The tire is inflated to ensure that all components are firmly adhered, allowing for a seamless fusion of materials.

The mold is then subjected to controlled heating, initiating the vulcanization of the rubber compound. This process is vital for enhancing the tire's resilience and flexibility, as it facilitates the formation of new molecular bonds within the rubber. The heat and pressure applied during this stage are meticulously adjusted to suit the tire's specifications, ensuring a balance between performance and durability.

Curing times are tailored to the tire's size and application, spanning from a brief 10 minutes to a thorough 30 minutes. Throughout this period, the tire's structural integrity solidifies, embedding the characteristics that define its functionality and safety. Once the curing is complete, the tire is ready for rigorous quality assessments, ensuring it meets all standards before distribution.

Quality Control and Final Inspection

After the vulcanization stage, each tire enters a critical phase of quality assurance. This involves a series of detailed evaluations to ensure that every tire meets high-performance and safety standards. Initially, skilled inspectors conduct a thorough examination to detect any surface imperfections, such as bubbles or irregularities in the tread design. This step is vital for identifying and rectifying issues that may have occurred during earlier stages of production, ensuring that each tire maintains the highest quality.

Moving beyond visual assessments, tires are subjected to advanced testing methods to verify their balance and structural integrity. Specialized machinery rigorously examines the tire's ability to maintain consistent road contact, which is essential for optimal driving performance and safety. These tests measure the tire's roundness and symmetry, ensuring smooth rotation without vibration or uneven wear when mounted on a vehicle. Ensuring balance is key to preventing any potential wobbling that could affect vehicle handling or passenger comfort.

Following successful completion of these rigorous tests, tires are prepared for market readiness. Each tire is marked with essential information, including size, type, and safety ratings, serving as a certification of its compliance with both regulatory and manufacturer standards. The tires are then carefully packaged to safeguard them during transportation and dispatched to distributors and customers, ready to deliver reliable performance on the road.

Tire Recycling and Environmental Considerations

Tire recycling has emerged as a crucial element in the tire industry's sustainability efforts. When tires reach the end of their lifespan, they can be transformed into useful materials rather than ending up in landfills. This process converts old tires into valuable resources, benefiting various sectors. For example, recycled tires can be ground into rubber mulch, which is popular in landscaping due to its resilience and ability to control weed growth. This repurposing not only extends the utility of tire materials but also alleviates the environmental impact of tire disposal.

In addition to landscaping, the rubber from recycled tires is utilized in creating athletic surfaces. These surfaces leverage the cushioning properties of rubber, offering safer and more comfortable environments for sports activities. In the construction sector, products made from recycled tires are incorporated into asphalt and concrete, enhancing the durability of these materials and reducing the need for new raw materials. These examples highlight the diverse applications of recycled tire materials and their significant role in promoting sustainable practices across industries.

Manufacturers are progressively promoting environmentally conscious methods in tire production as part of their ecological accountability. This includes researching alternative materials that lessen environmental impact and adopting production techniques that minimize waste and emissions. By concentrating on these areas, the tire industry aims to reduce its environmental footprint while upholding the performance and safety standards demanded by consumers.

Effective tire maintenance also significantly contributes to environmental preservation. Keeping tires properly inflated and regularly rotated can greatly prolong their lifespan, delaying the point at which they become waste. By maintaining tires in optimal condition, vehicle owners can decrease the frequency of replacements, thus reducing the total number of tires needing disposal. This approach not only benefits the environment by cutting down on waste but also provides economic advantages to vehicle owners through extended tire life.

The tire manufacturing process is a testament to human ingenuity and the constant pursuit of innovation in the automotive industry. As technology advances and environmental concerns grow, tire manufacturers will continue to adapt and improve their processes to create even safer, more efficient, and more sustainable tires for the future. If you're in the market for new tires, shop for tires online and let us help you find the best deals to keep you rolling smoothly and safely on the road.

Ready to find the perfect tires?

Search By